A Beginner’s Guide to Understanding the Functionality of Industrial Scales

A Beginner’s Guide to Understanding the Functionality of Industrial Scales

Blog Article

All Concerning Industrial Scales: Key Attributes and Benefits for Your Office

Industrial ranges are crucial in boosting functional effectiveness throughout numerous fields, offering features such as high capability, precision accuracy, and durable building and construction. Recognizing the varied kinds and applications of commercial scales can offer useful understandings right into enhancing your work environment procedures-- yet, the journey doesn't end there.

Kinds Of Industrial Scales

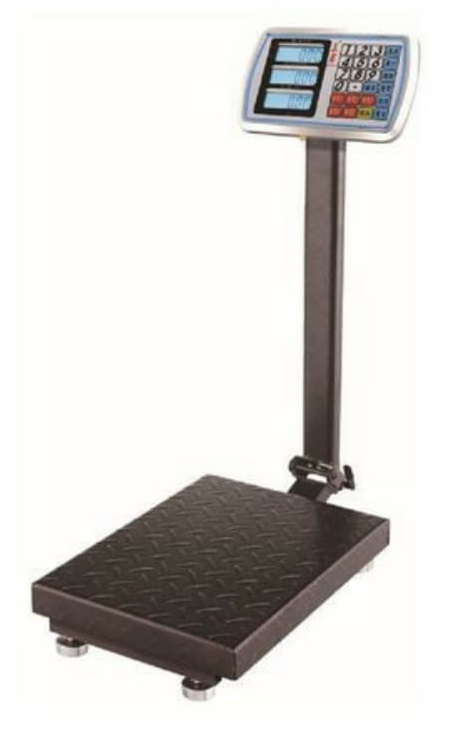

Industrial ranges are crucial tools used throughout numerous sectors for accurate weight measurement. They can be found in numerous kinds, each created to satisfy details applications and settings. One typical type is the platform scale, which offers a large considering surface area suitable for bulky and hefty items. These ranges are frequently used in warehouses and delivery centers.

An additional common type is the bench range, which is appropriate and compact for smaller things. These ranges are frequently located in retail and food service settings, where fast and accurate dimensions are required. Flooring scales offer a similar objective however are designed for durable applications, permitting the evaluating of large pallets and containers straight on the ground.

Moreover, electronic ranges have actually acquired appeal due to their simplicity of usage and accuracy. They frequently include advanced electronic devices that enhance performance, such as connectivity alternatives for information tracking. Furthermore, mobile ranges provide versatility for on-the-go weighing, making them very useful in fields like agriculture and logistics.

Recognizing the various types of commercial ranges is important for choosing the appropriate equipment to satisfy certain functional demands, ensuring effectiveness and accuracy in weight dimension.

Key Features of Industrial Scales

When choosing the proper sort of commercial range, it is essential to consider the essential functions that improve their capability and viability for specific applications. One of the most important features is the scale's capability. Industrial ranges are available in various weight capabilities, ensuring that they can fit the needs of various industries, from light materials to hefty lots.

One more essential function is precision. High-precision load cells are essential for making certain that measurements are consistent and reputable, which is crucial for supply monitoring and top quality control. In addition, the readability of the display screen plays a substantial duty; clear, electronic display screens with flexible illumination permit simple viewing in various lighting problems.

Toughness is one more key particular, with lots of industrial ranges designed to stand up to severe atmospheres, consisting of exposure to wetness, chemicals, and hefty use. Some models also include water resistant or stainless-steel building and construction. Connectivity alternatives such as Bluetooth or USB enable smooth data transfer and combination with various other systems.

Advantages for Ergonomics

In addition, commercial ranges make it possible for faster processing times. With automated weighing solutions, workers can rapidly acquire weight information without hands-on estimations, releasing up time for other important jobs. This velocity in operations not just improves operational performance but also helps meet manufacturing deadlines more efficiently.

Furthermore, industrial ranges offer useful information that can be analyzed for continual renovation. By checking weight patterns, businesses can determine inefficiencies in their procedures and implement rehabilitative actions, eventually leading to enhanced efficiency.

The combination of these ranges likewise sustains compliance with industry guidelines, as accurate coverage of weights is typically called for. This minimizes the risk of pricey penalties and improves the company's track record for reliability. Industrial Scales. On the whole, the consolidation Clicking Here of commercial scales adds to a more effective, cost-effective, and compliant office environment

Applications in Different Industries

In the food industry, industrial ranges are made use of for section control, dish solution, and conformity with wellness laws, assuring food safety and security and uniformity. Likewise, in the pharmaceutical market, precise evaluating is vital for medication formula, where even minor discrepancies can lead to substantial regulatory concerns and safety and security problems.

Building and construction and logistics markets also gain from commercial scales, as they aid in taking care of basic materials and optimizing delivery processes. By giving precise weight information, these scales facilitate much better load preparation and compliance with transportation guidelines.

Additionally, the farming industry uses industrial ranges for evaluating animals, feed, and produce, consequently improving functional efficiency and making certain fair profession techniques.

Maintenance and Calibration Tips

To make certain optimal efficiency and long life of industrial scales, normal upkeep and calibration are vital. Operators needs to routinely clean up the range to protect against debris buildup, which can affect accuracy.

Calibration is just as essential; it makes sure that the range supplies exact readings in accordance with market requirements. It is a good idea to adjust ranges frequently-- at least annually or more frequently if the scale is used heavily or relocated regularly. Adhere to the supplier's standards for calibration procedures, which usually consist of making use of licensed calibration weights.

Additionally, preserving appropriate environmental problems, such as temperature level and moisture control, can improve scale performance and precision. Last but not least, educating personnel on appropriate usage methods will even more protect against abuse that can bring about errors or damage. By sticking to these upkeep and calibration ideas, companies can ensure their commercial scales operate successfully, eventually Full Report supporting performance and compliance with regulatory criteria.

Verdict

In recap, industrial scales offer as vital instruments for boosting work environment visit this site right here performance across diverse markets. By recognizing the essential attributes and advantages of industrial scales, companies can utilize these tools to improve material use, lower waste, and ultimately drive efficiency.

Industrial ranges are crucial in enhancing operational efficiency across different markets, supplying features such as high capability, precision accuracy, and durable construction.When selecting the suitable kind of commercial scale, it is crucial to think about the crucial attributes that boost their functionality and suitability for certain applications. By providing accurate weight measurements, industrial scales get rid of the possibility for human error, making certain that materials are considered consistently and specifically. It is recommended to adjust scales regularly-- at the very least as soon as a year or more often if the range is used heavily or relocated regularly. By understanding the essential functions and benefits of commercial scales, companies can take advantage of these tools to enhance material utilization, lower waste, and inevitably drive performance.

Report this page